SMD PCB Assembly in Pune

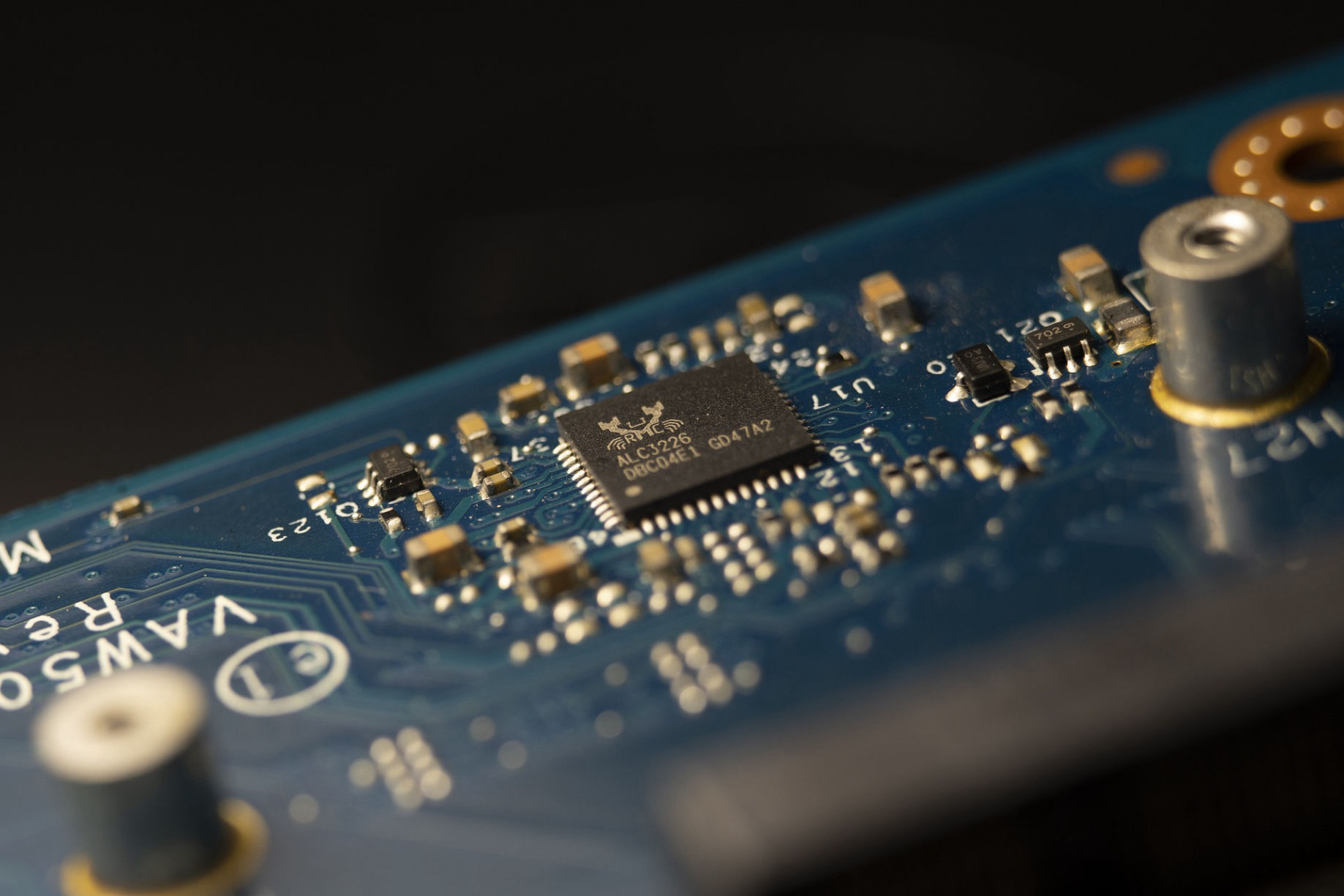

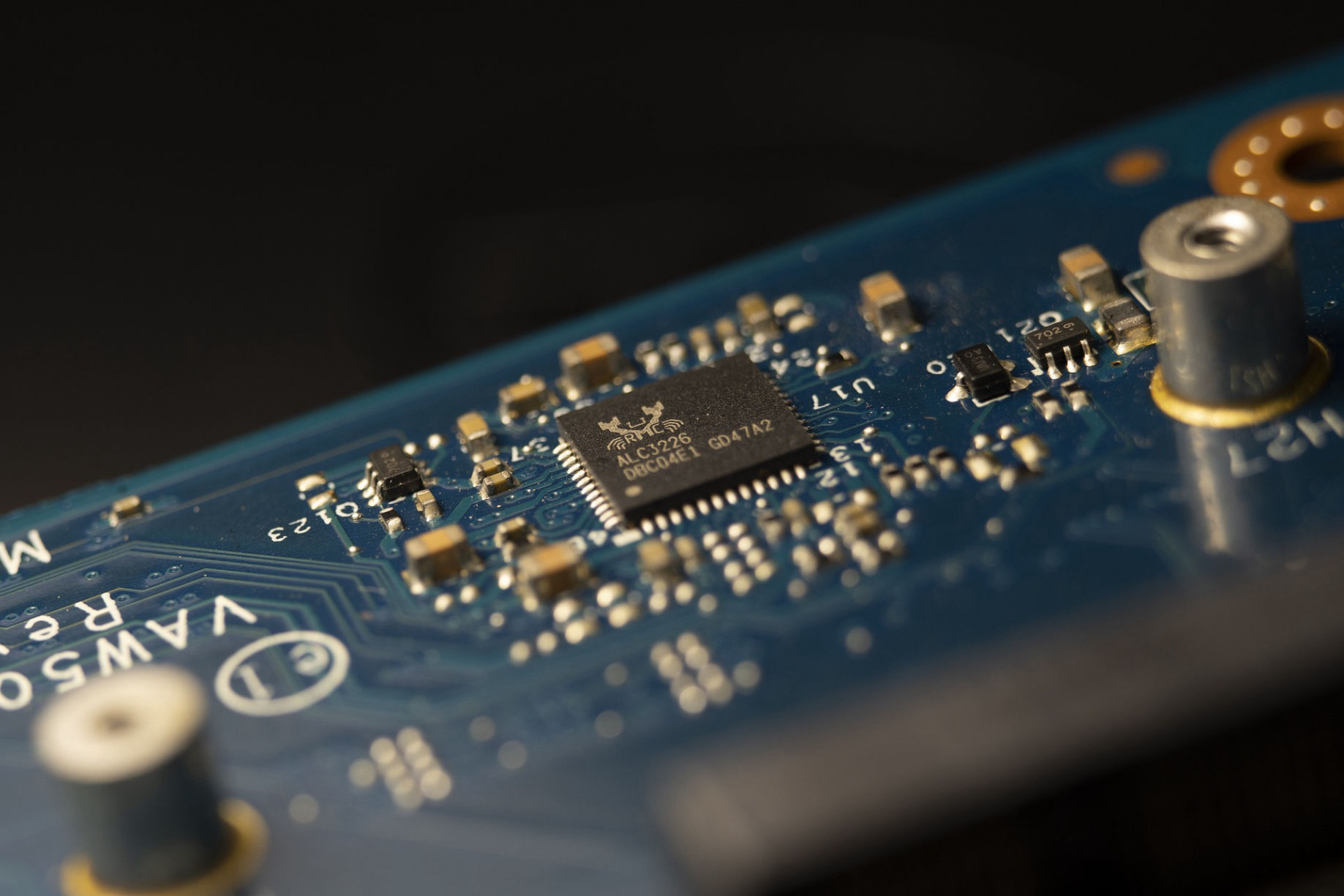

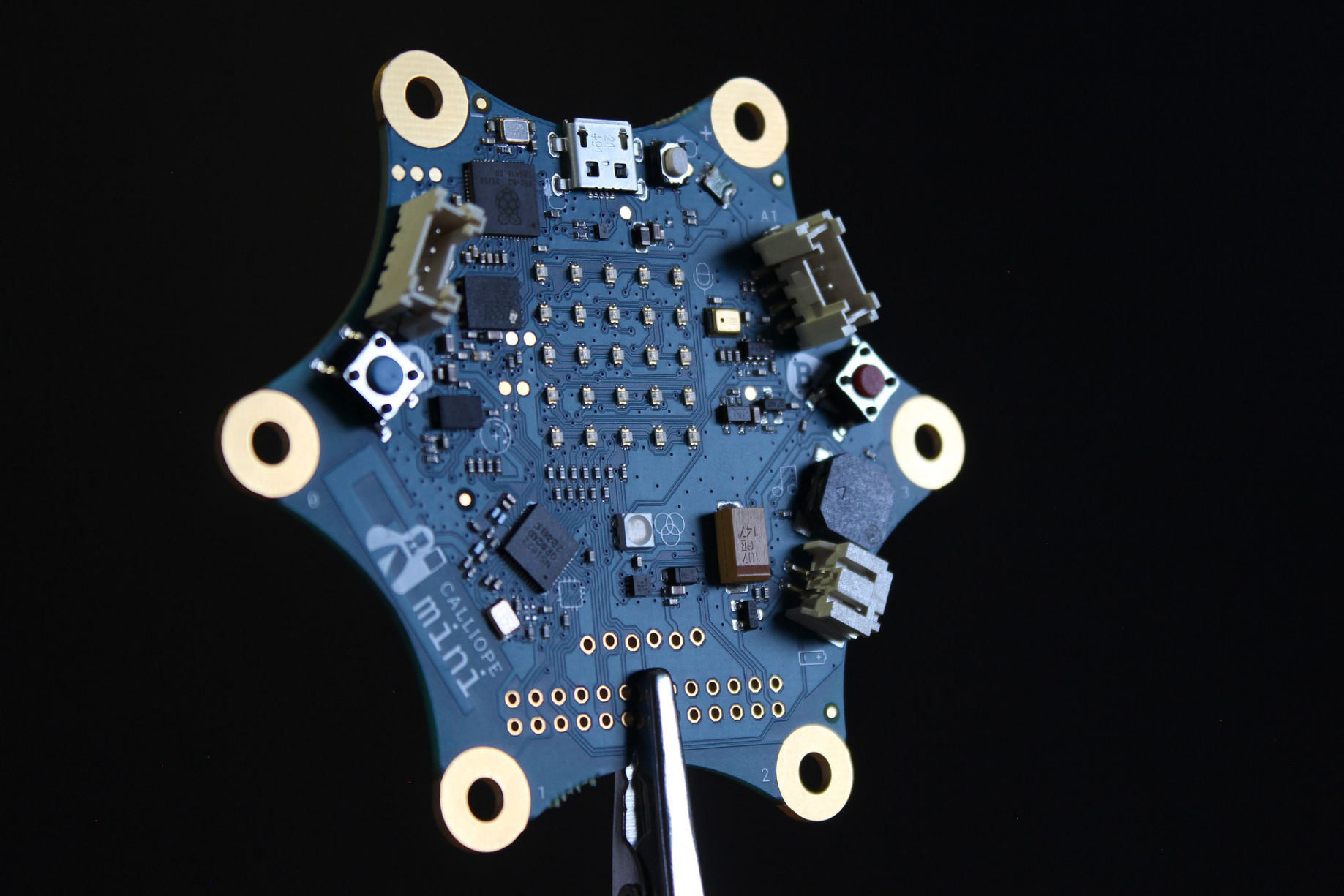

Surface Mount Technology (SMT) Assembly

Our SMT assembly services leverage advanced equipment and techniques to place components on PCBs with high accuracy and speed. This process is ideal for complex, high-density designs.

At Microconnect Engineers, we specialize in providing top-notch PCB Assembly services designed to meet the precise needs of our clients across various industries.

Our commitment to quality, efficiency, and innovation ensures that every project is completed to the highest standards. Here’s an overview of our PCB Assembly capabilities

Tailored services to meet your unique needs and challenges.

Ensuring timely delivery of products and services with precision and reliability.

Top Notch Quality with Precision: Delivering Excellence with Unmatched Accuracy.

Innovating the Future with Cutting-Edge Solutions and Breakthrough Advancements.

Ensure complete confidentiality of project details and intellectual property at all stages of development.

Ensuring 100% customer satisfaction through exceptional service, quality, and reliability.

Our SMT assembly services leverage advanced equipment and techniques to place components on PCBs with high accuracy and speed. This process is ideal for complex, high-density designs.

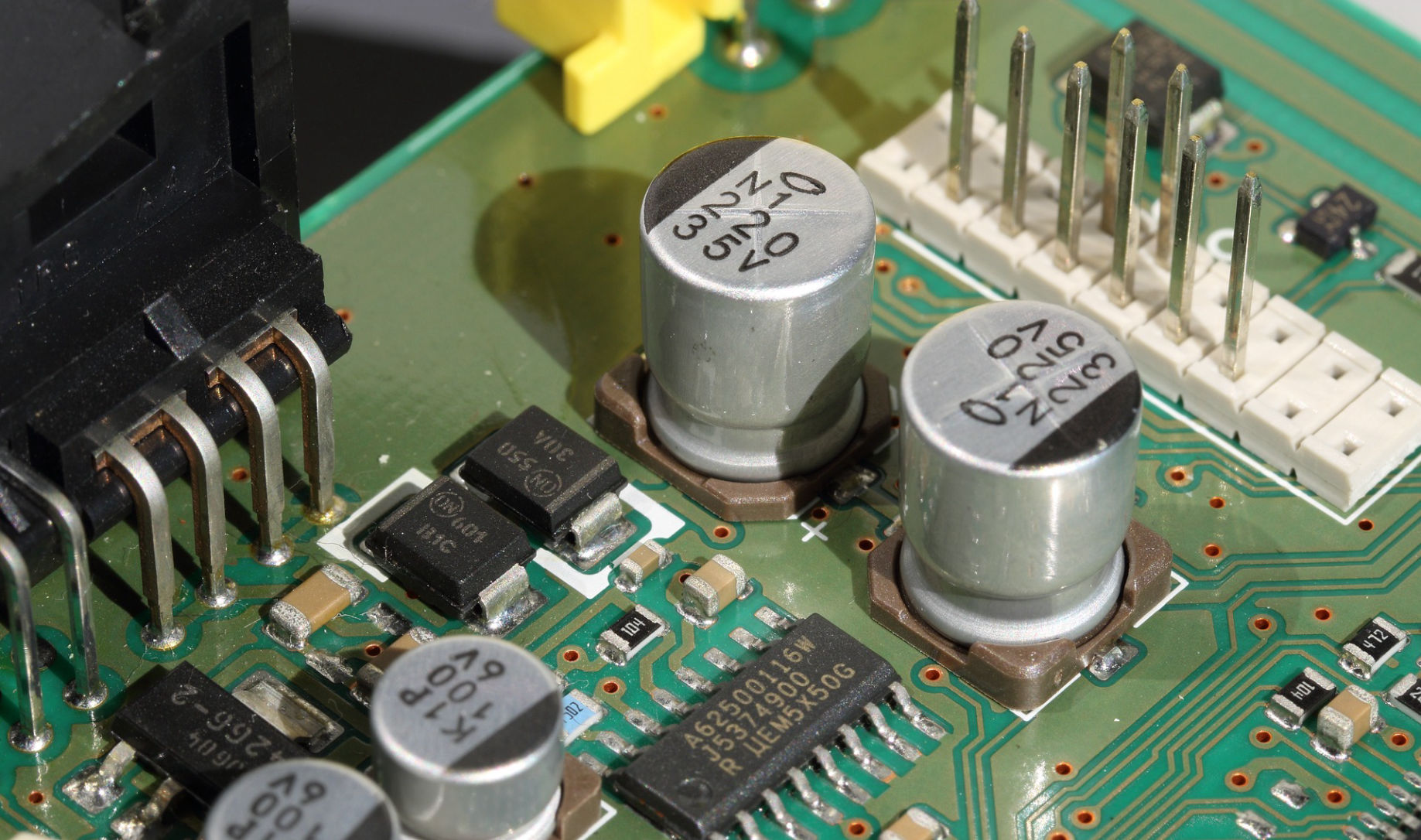

For applications requiring strong mechanical bonds and reliability, our THT assembly services provide robust solutions. This method is ideal for components that need to withstand high stress or high temperatures.

We offer mixed technology assembly services that combine SMT and THT techniques, providing flexible solutions for complex electronic designs.

Hybrid Solutions: Seamlessly integrate surface mount and through-hole components on a single board, optimizing space and functionality.

Versatility: Ideal for products that require both high-density component placement and robust mechanical connections.

We understand the importance of quick turnaround times and flexibility for prototype and low-volume projects. Our dedicated prototype assembly services help you bring your concepts to life swiftly and efficiently.

Rapid Prototyping: Fast and reliable prototype assembly services to validate and refine your designs.

Custom Solutions: Tailored assembly solutions to meet your specific project requirements, from single prototypes to small production runs.

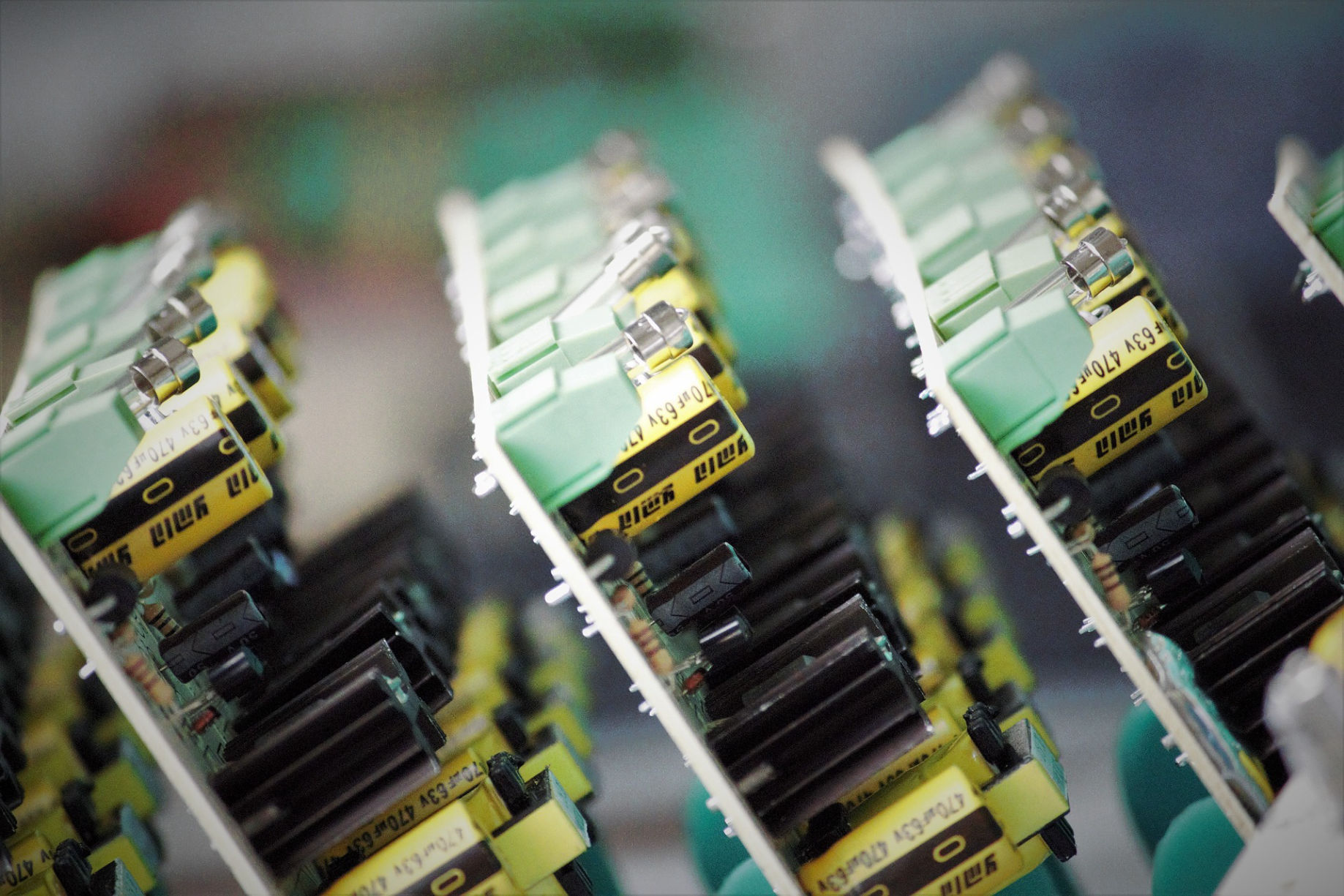

Our advanced facilities are equipped to handle high-volume production runs with consistent quality and efficiency. We ensure that every PCB assembly meets the exact specifications and standards required.

Scalability: Efficient processes and scalable infrastructure to accommodate large production volumes.

Cost-Effective Solutions: Competitive pricing and optimized production workflows to deliver cost-effective assembly services without compromising on quality.

Quality is at the heart of our PCB assembly services. We adhere to strict quality control processes and industry standards to deliver reliable and high-performance assemblies.